- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Understanding the Impacts of X-ray Source Size on the Performance of Polycapillary X-ray Optics

Brendan Waffle

Understanding the Impacts of X-ray Source Size on the Performance of Polycapillary X-ray Optics

Brendan Waffle

Brendan Waffle

X-ray source size plays a pivotal role in determining the efficiency and performance of polycapillary X-ray optics. These optics, designed to focus or collimate X-ray point sources or beams, are widely used in applications such as micro X-ray fluorescence (µXRF), X-ray diffraction (XRD), and confocal XRF. The interaction between the X-ray source size and polycapillary optics directly influences beam intensity, resolution (output focal spot size), and overall system capability. This article explores the significance of X-ray source size, its effect on polycapillary optic performance, and its implications for a wide array of scientific, industrial, and medical applications.

The X-ray source size refers to the dimensions of the point or area from which X-rays are generated within an X-ray tube. For systems employing polycapillary optics, the source size is critically important because it dictates how effectively the optics can focus or transmit X-rays. A mismatch between source size and the acceptance angle of polycapillary fibers can significantly impact system performance, as the optics are designed to work optimally with specific source geometries.

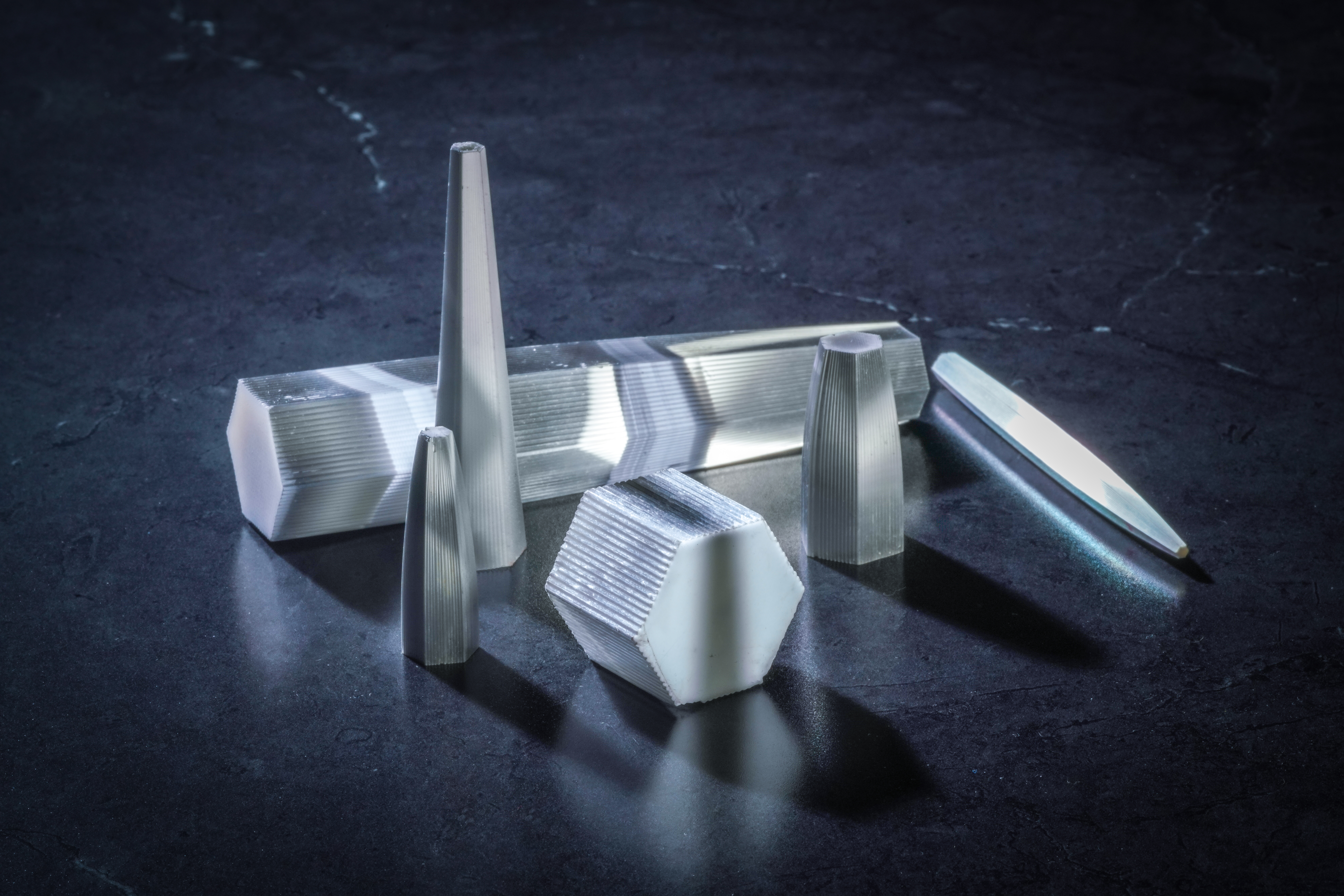

Polycapillary optics consist of bundles of hollow glass capillaries, which guide X-rays through total external reflection. These optics can focus or collimate X-ray point sources or beams with remarkable precision, but their performance is heavily influenced by the size of the X-ray source. Here's why the source size is critical:

The interplay between source size and polycapillary optics is evident across several advanced X-ray applications:

1. Micro X-ray Fluorescence (µXRF)µXRF benefits significantly from small X-ray source sizes, often in the micron range. Using polycapillary optics, an X-ray beam can be focused onto a tiny spot for elemental mapping and analysis of features at the microscale. This is particularly valuable in fields like electronics (e.g., solder joint analysis), forensics (trace evidence examination), geological science (mineral composition studies), and biology (tissue scanning). Smaller sources allow precise beam concentration, improving detection sensitivity and spatial resolution.

2. X-ray Diffraction (XRD)XRD leverages collimated or focused X-ray beams to study the crystallographic structure of materials. Here, the source size affects the divergence of the beam and, subsequently, the accuracy of lattice parameter measurements and phase distribution analysis. By pairing polycapillary optics with micro-focus X-ray sources, systems can achieve sharper diffraction peaks and reduced background noise, ensuring more dependable results in material science, pharmaceuticals, and semiconductor research.

3. Confocal XRFConfocal XRF employs polycapillary optics to create overlapping focal points from excitation and detection beams, enabling 3D elemental analysis. A small X-ray source is crucial to narrow the focal volumes and enhance spatial resolution. This approach is advantageous for analyzing layered materials, coatings, and hazardous samples, where both sensitivity and depth resolution are essential.

Related: Five Things to Consider When Coupling a Polycapillary X-ray Optic With an X-ray Source

A polycapillary optic captures a large solid angle of X-rays from an X-ray source and redirects them to a micron-sized focal spot or a highly collimated beam. The X-ray intensity achieved with such optics is a few orders of magnitude higher than that obtained with conventional pinhole collimators, contributing to the significantly improved X-ray analysis performance in detection sensitivity, spatial resolution, measurement speed, and precision. XOS optics are widely used in commercial instruments and customized X-ray analysis systems for various industrial and research applications in the fields such as microelectronics, semiconductor manufacturing, pharma, and life sciences.

While smaller X-ray sources offer significant benefits, they also present challenges when integrated with polycapillary systems:

Micro-focus sources concentrate a high amount of energy into a small area, resulting in intense heat generation. Without efficient cooling mechanisms, this can damage the X-ray tube or reduce its lifespan. Advanced designs, such as liquid cooling systems, are often required to manage this heat effectively. In some cases, air cooling can be enough depending on the tube power.

Reducing source size results in a decrease of the source output beam intensity, as these systems typically must run at lower power (lower current specifically) compared to standard sized X-ray sources. This means it may be challenging to find a source that is optimal for polycapillary optic pairing as it must balance power and source size to maximize performance.

Smaller sources require precise alignment with polycapillary optics, adding complexity to system design. Additionally, such systems are often more expensive to manufacture. Collaborating with experts in X-ray optics helps strike the right balance between source size, performance, and cost.

Continuous advancements are optimizing the synergy between X-ray source size and polycapillary optics:

Selecting the ideal X-ray source size involves a careful evaluation of several factors:

Related: Maximizing Polycapillary Optic Performance: Choosing the Perfect X-ray Source and More

The size of an X-ray source holds a profound impact on the performance of polycapillary X-ray optics. A well-matched source size unlocks the full potential of these optics, enhancing resolution, beam intensity, and application versatility. From µXRF and XRD to confocal XRF, understanding and optimizing this relationship is key to achieving precision and efficiency in cutting-edge X-ray systems.

By choosing thoughtfully designed technologies and consulting with X-ray optics experts, you can harness the capabilities of polycapillary optics for your most demanding projects.

With over 5 years of experience designing X-ray optics and repairing X-ray equipment, Brendan Waffle brings a proven track record of surpassing customer expectations and pioneering innovative solutions. Acknowledged as a strategic partner by XOS customers, Brendan goes beyond being just a consultant, demonstrating a unique ability to tailor customized solutions for national labs, universities, and X-ray equipment manufacturers.

Helping customers devise innovative solutions is my passion,” Brendan affirms, emphasizing his dedication to driving advancements in the field of X-ray optic design.

If you'd like to get in touch with Brendan or one of our other experts, click here.