- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Sindie Online Enables Cost Savings in Biorefinery by Optimising Production with Real-time Results

The demand for biofuels has increased in recent years, with the EU requiring that 10% of the total transport fuel in its member countries to come from a renewable energy source in 2020 1. In addition, the U.S. Energy Information Administration anticipates between 18-55% growth in biofuels production over the next 30 years 2. While biofuels typically contain little sulphur, they are still required to meet fuel quality compliance specifications either for use in vehicles, or as a blending feed for traditional refinery fuels. As such, biorefineries must measure the sulphur in their product to ensure it is below regulatory limits, typically less than 15 ppmw. In addition to this, due to the variety of feedstocks, online analysis of biofuels can be challenging due to changing sample composition.

XOS’ Sindie® Online total sulphur analyser uses Monochromatic Wavelength Dispersive X-ray Fluorescence (MWDXRF) to continuously and nondestructively measure a sample stream and deliver results at user-defined intervals. The analyser uses a Dynamic Window Module (DWM) to automatically replace the sample window which effectively eliminates any drift and significantly reduces the frequency of required calibrations. This, in addition to the rugged design of the analyser, reduces the time and frequency of required maintenance leading to an uptime as high as 98%

In August of 2019, a Sindie online total sulphur analyser was installed at the Malchin biofuels refinery of ecoMotion GMBH by 360KAS, XOS’ exclusive distributor in Northwestern Europe. This site is one of the first biodiesel pilot plants built in Germany and has been in operation since 2001. The primary feedstocks for this plant are animal fats, vegetable oils, and used cooking oil. This site produces 10,000 tons of biodiesel annually.

The core process in biodiesel production is transesterification. In this chemical exchange reaction, the glycerine contained in the primary material is replaced with methanol. This leads to the formation of fatty acid methyl esters and glycerine. When converting animal fats and used cooking oil, the production process has two additional steps that are not required in conventional biodiesel production. In the first step – prior to transesterification – the free fatty acids contained in the primary material are esterified. After transesterification, the product is distilled. The result is an extremely pure, crystal-clear, and almost colourless product.

ecoMotion Biofuel Plant in Malchin, Germany

The expectation of this analyser was to continuously measure the sulphur concentration in the final product to confirm the site was producing a product compliant with automotive fuel specifications. Previously this required the site to send samples to a remote laboratory which introduced delays and uncertainty in their production. By installing Sindie online sulphur analyser, the site obtains a measurement every 5 minutes, enabling them to optimise their production, be confident their product is compliant and of high quality, and reduce their gas consumption by 5%.

Almost a year after installation, the site has reported that their expectations for the performance of the analyser continue to be met, the analyser continues to operate without any problems, and the measured values match their laboratory cross-checks.

ULTRA-LOW SULPHUR ANALYSIS IN PETROLEUM PROCESS STREAMS USING MWDXRF

Refiners are challenged to produce higher-quality products while trying to maximize efficiency. In the last decade, national regulators in places like the US, Europe, China, and India have implemented or plan to implement requirements for total sulphur in gasoline and diesel levels as low as 10 ppm. Increased hydrotreating and modifying crude slate are some of the levers that can be pulled to help lower sulphur levels in finished products. Simultaneously, there are global initiatives to increase the percentage of biofuels produced using renewable feedstocks. In order to meet these lower sulphur levels, refineries must invest in new or upgraded equipment, modify operations or a combination of both. Regardless, it will increase the cost of producing diesel and gasoline.

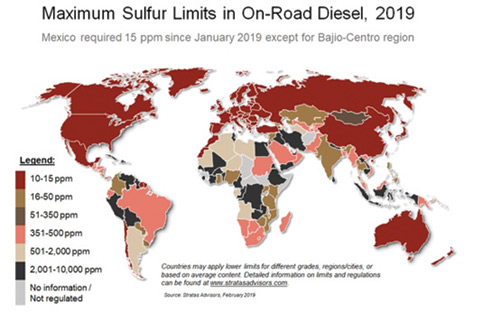

Figure 1: 2019 Global Maximum Sulphur Limits

In order to meet renewable fuel usage targets, new standalone biofuel refineries have been constructed to produce biofuel from a variety of feedstocks, and some traditional refineries have been upgraded to allow for biofuel feedstocks to be used, or completely converted into biofuel refineries. Biofuels present some interesting challenges from an online sulphur measurement standpoint. Some biofuels naturally have such low sulphur, there are few or no additional procedures or units required to further reduce the sulphur content, while others require typical sulphur removal units such as a hydrotreater. However, all biofuels must meet regulated sulphur specifications such as EN 14214, and must be measured and certified to such specifications before being sold.

In addition, it can be very valuable to know the specific sulphur content of a given biofuel being used for blending with traditional refinery fuels in order to reduce sulphur giveaway. Of course, it is also highly profitable to measure biofuels where they need to be treated to remove sulphur. A refiner can use a sulphur measurement to reduce hydrogen gas consumption and optimise catalyst usage. The challenge, then, is how to condition and measure biofuels, especially when the feedstock can change and alter the sample conditioning requirements.

Changing feedstocks will always cause complications, as a given analyser will typically be fine-tuned to operate with certain specifications such as pressure, temperature, flow rate, viscosity, density, composition, and filtration. This becomes readily apparent with analyser that require sample conversion before analysis. XRF analyser offer a unique resiliency to this as it is a non-destructive method that does not require the sample to be combusted, mixed with solvents, or adjusted for density to report ppmw properly. In addition to this, due to the nature of XRF, the analyser is resilient to sulphur concentration changes whether it is 10 ppmw, 100 ppmw, or 1000 ppmw, though a calibration and validation program designed for the measurement range of interest will always improve precision. For such a dependable system, the value the analyser provides then comes from its accuracy and precision.

For every part per million of sulphur removed, a refinery spends significant money on capital, hydrogen, catalyst, and energy. The related downtime to catalyst changeout must also be factored into the equation. Catalyst has a finite life, and that length of time is dictated by how the hydrotreater is operated. By varying temperature, space velocity, and hydrogen partial pressure, sulphur removal and catalyst life are impacted. A refiner may choose to vary the specific feedstocks used in order to reduce the total sulphur content entering a hydrotreater for the purpose of minimizing the required use of sulphur removal equipment, though this will come at a cost, either in the form of higher purchase price, or by higher concentrations of other contaminants.

Regardless of what method is utilized to produce biofuels at these lower sulphur levels, monitoring sulphur levels will be critical in controlling costs. Optimisation is dependent on knowing the sulphur levels at all times, accurately and reliably.

TOTAL SULPHUR METHODOLOGIES AND TECHNOLOGIES

There are a number of different technologies available on the market for testing sulphur in liquid petroleum products, due to regulations and requirements around the world. Table 1 outlines the different relevant technologies and their Maximum Sulphur Limits in On-Road Diesel, 2019 3 correlating methods. Process analysers based on these technologies typically correlate to the respective laboratory method, or in some cases may have a method of their own.

| Table 1: Total Sulphur Methods | |||

|---|---|---|---|

| ASTM Method | Technology | Range | Scope Fuel Types |

| D2622 | WDXRF | 3 ppm - 4.6 wt.% | Diesel fuel, jet fuel, kerosene, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, gasoline-ethanol blends, and biodiesel |

| ISO 20884 | WDXRF | 5 mg/kg – 500 mg/kg 5 mg/kg – 45 mg/kg |

Diesel fuels containing up to about 30% (V/V) fatty acid methyl esters (FAME), motor gasolines containing up to about 10% (V/V) ethanol, Synthetic fuels such as hydrotreated vegetable oil (HVO) and gas to liquid (GTL) having sulphur contents in the range of 5 mg/kg to 45 mg/kg. |

| D4294 | EDXRF | 17 ppm – 4.6 wt.% | Diesel fuel, jet fuel, kerosene, other distillate oil, naphtha, residual oil, lubricating base oil, hydraulic oil, crude oil, unleaded gasoline, gasolineethanol blends, biodiesel, and similar petroleum products |

| ISO 13032 | EDXRF | 8 mg/kg – 50 mg/kg | Automotive gasoline containing up to 3,7 % (m/m) oxygen, diesel fuels [including those containing up to about 10 % (V/V) fatty acid methylester (FAME)] |

| D5453 | UVF | 1.0 – 8000 ppm | Liquid hydrocarbons, boiling in the range from approximately 25 to 400°C, with viscosities between approximately 0.2 and 20 cSt at room temperature. Including naphtha, distillates, engine oil, ethanol, FAME, and engine fuel such as gasoline, oxygen enriched gasoline (ethanol blends, E85, M85, RFG), diesel, biodiesel, diesel/ biodiesel blends, and jet fuel. |

| ISO 20846 | UVF | 3 mg/kg – 500 mg/kg 3 mg/kg – 45 mg/kg |

Motor gasolines containing up to 3,7 % (m/m) oxygen [including those blended with ethanol up to about 10 % (V/V)], diesel fuels, including those containing up to about 30 % (V/V) fatty acid methyl ester (FAME), Synthetic fuels, such as hydrotreated vegetable oil (HVO) and gas to liquid (GTL). |

| D7039 | MWDXRF | 3.2 – 2822 ppm | Gasoline, diesel fuel, jet fuel, kerosene, biodiesel, biodiesel blends, and gasoline-ethanol blends |

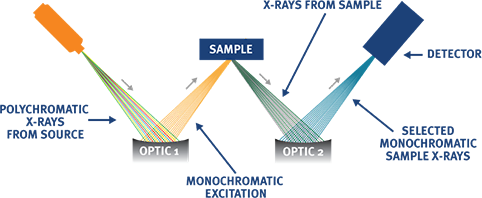

Figure 2: Typical MWDXRF Setup

In this paper, we will discuss the performance and precision of the ASTM D7039 method using MWDXRF technology, which also complies with ISO 20884. This technique utilizes high-performing doubly curved crystal (DCC) optics coupled with a low-power X-ray tube, creating a low-maintenance, highly precise technology. MWDXRF is a simplified and highly robust X-ray technique which provides sub-1 ppm sulphur detection. An MWDXRF analyser engine (Figure 2) consists of a low-power X-ray tube, a point-to-point focusing optic for excitation, a sample cell, a second focusing optic for collection, and an X-ray detector. The first focusing optic captures a narrow bandwidth of X-rays from the source and focuses this intense, monochromatic beam to a small spot on the sample cell. The monochromatic primary beam excites the sample and secondary characteristic fluorescence X-rays are emitted. The second optic collects only the characteristic sulphur X-rays and focuses them on the detector. The analyser engine has no moving parts and does not require consumable gasses or high temperature operations.

MWDXRF removes the scattered background peak created by the X-ray tube increasing the signal-to-background ratio (S/B) by a factor of 10 compared to conventional WDXRF technology. The S/B is improved by using the monochromatic excitation of the X-ray source characteristic line. Additionally, the focusing ability of the collection optic allows for a small-area X-ray counter, which results in low detector noise and enhanced reliability.

The WDXRF technique has been an accepted practice for measuring sulphur in petroleum liquids for many years. However, when the first regulations requiring sulphur in diesel moved to 15 ppm or less in 2006, improvements to the analytical instruments and a revision of the method was required to meet the need of new regulations. Similar evolution of the UVF method has taken place while EDXRF has not yet established itself as a viable ultra-low sulphur measurement technique. MWDXRF, on the other hand, was developed specifically to address the needs of refiners and petroleum distribution partners for a simple measurement technique, ideally suited for single-element, ultra-low sulphur measurements.

The ASTM D7039 method (MWDXRF) is essentially a subset of ASTM D2622 (WDXRF) with some important distinctions. The excitation X-ray beam of a WDXRF instrument is polychromatic whereas the MWDXRF excitation beam is monochromatic. For both, the output of the X-ray tube comprises the characteristic energy of the target element and the Bremsstrahlung spectral energy associated with the production X-rays by electron acceleration in a vacuum tube. The target element is chosen for a characteristic X-ray just high enough in excitation energy to produce X-ray fluorescence of the element of interest (sulphur), but low enough to minimize background scattering.

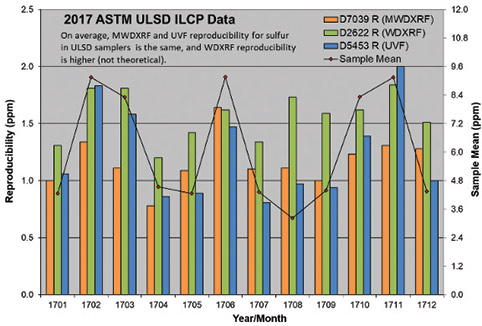

VALUE OF PRECISION

American Society for Testing and Materials (ASTM) methods such as D7039 require full precision statements that include a repeatability and reproducibility component. Repeatability (r) is the variation of two measurements within a 95% confidence interval taken on one instrument of the same sample under the same operating conditions. Reproducibility (R) is the variation of running the same sample at different test sites using similar equipment. The ASTM D7039 precision statement was updated in 2013 to include a repeatability (r) for all products of 0.4998 * X0.54 and a reproducibility (R) for all products of 0.7384 * X0.54. With process instrumentation, reproducibility becomes critical. If the process can be continuously and quickly monitored, variation can be identified and optimisation can be handled. As compared with the other methodologies in Table 1, D7039 offers superior reproducibility from 5-10ppm which is critical to meet ultra low sulphur regulations. As seen in Figure 3, MWDXRF provides better reproducibility at the Tier 3 levels of 15 ppm sulphur in ULSD. This R value can help a refiner justify the economics of installation quickly when process optimisation can be achieved faster.

Note that the precision statements for ASTM D7039 for the MWDXRF technique are based on the range of the method, 3.2 to 2,822 ppm, which far exceeds the needs, when interested in measuring sulphur in finished product such as highway diesel or gasoline. The Interlaboratory Study #761 results, gathered and analysed in accordance with ASTM D6300 methodology for sulphur samples limited to ≤25 ppm show that the repeatability (r) = 1.1 ppm and the reproducibility (R) = 1.3 ppm.

Figure 3: ASTM Interlab Cross-Check Data for ULSD 2017

CONCLUSION

The most important characteristics of a valuable analyser are reliable performance, a high degree of uptime, superior stability, and satisfactory reproducibility, especially in the range of ≤10 ppm for sulphur. Delivering superior precision at the control target is critical to sulphur measurements—even more valuable than the lowest possible detection limit. Powered by MWDXRF, Sindie Online delivers the precision, hassle-free operation, and flexibility to meet the application needs of the industry’s dynamic landscape.

To learn more about our biofuels solutions,

visit xos.com/biofuels.

Author:

Author:

Evan Thomas,

Product Manager – Process Analysers

Sign up to chat with an XOS expert 1-on-1!

visit xos.com/virtualchats.

REFERENCES:

1. https://ec.europa.eu/energy/topics/renewable-energy/biofuels/overview_en

2. https://www.eia.gov/todayinenergy/detail.php?id=43096

Sindie® Online is an industrial grade process sulphur analyser with breakthrough detection capability to monitor ultra low sulphur in petroleum or aqueous process streams. This process analyser presents the ultimate solution for refineries and pipeline terminals where measurement speed and reliability are essential. Powered by MWDXRF®, Sindie Online uses ASTM D7039 technology and delivers real-time, continuous analysis of total sulphur from 0.5 ppmw up to 3000 ppm

Learn More

Sindie +Cl delivers exceptional reproducibility for both sulphur and chlorine analysis with one push of a button and zero hassle. Samples are measured directly, which means it can analyze even the heaviest of hydrocarbons like crude oil or coker residuals, without the hassle of boats, injectors, furnaces, or changing detectors.

Sindie +Cl is powered by Monochromatic Wavelength Dispersive X-Ray Fluorescence (MWDXRF®): an elemental analysis technique offering significantly enhanced detection performance over traditional XRF technology. Using the industry’s most advanced optics, doubly curved crystals, Sindie +Cl achieves a high signal-to-background ratio and delivers very precise measurements of low sulphur and chlorine.

Sindie 2622 complies with ASTM D2622, D7039 and ISO 20884 methods, enabling complete flexibility in sulphur analysis. No compromises in detection, performance and reliability — it is the ideal sulphur analytic solution from crude feedstocks and intermediates to low sulphur biofuels.

Learn More