- Analyzers

- Optics & Sources

- Technologies

- Support

- About

A New Solution to Eliminate Centrifuge for Sulfur in Crude Oil Analysis

BACKGROUND

PRODUCT SPOTLIGHT

Petra MAX™ delivers advanced D4294 sulfur analysis in addition to 12 elements from P to Zn including Ni, V, and Fe. This robust benchtop analyzer complies with ASTM D4294 and ISO 8754 for measuring sulfur in hydrocarbons. Petra MAX is powered by HDXRF, utilizing XOS patented doubly curved crystal optics coupled with a high-performance silicon drift detector and an intense monochromatic excitation beam. This industry-leading technology reduces background noise and increases signal-to-noise output, enabling low detection limits and high precision without the need for consumable helium gas, a vacuum pump, or extensive sample preparation.

Test methods for measuring sulfur content, like ASTM D4294 and ISO 8754, have become critical for assessing the value of crude oil. These methods utilize X-ray Fluorescence (XRF) analysis, and with any method, it is important to consider the interferences inherent within the analysis technique. The ASTM D4294 standard test method references matrix effects as a known interference, which may influence the sulfur measurement in crude oil and produce biased results.

CHALLENGE

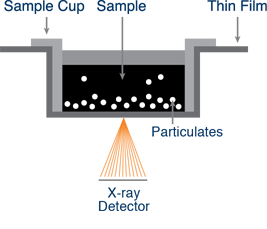

Crude oil presents unique challenges for ASTM D4294 analysis. While sulfur containing compounds in crude oil are primarily comprised of organosulfur compounds that remain homogeneous in hydrocarbons, interferences like Si, Ca, Cl, Fe and water are commonly present and will settle to the bottom of a sample over time. These interferences can absorb the X-ray signal and reduce the concentration of sulfur reported. While many D4294 instruments (traditional XRF) can correct for interfering elements, interferences that settle in crude oil can create challenging scenarios. Diagram A demonstrates settling over a period of 60 minutes.

Diagram A: Particulate Settling

Particulate solids and water have shown to cause underreported sulfur measurements by as much as 40%. Such a significant error can cause misclassification of sour crude oil as sweet crude oil. With global regulatory trends lowering sulfur levels in refined products from diesel to marine fuel, underreporting sulfur may cause refiners to miscalculate the costs associated with processing incoming crude oil. Because D4294 instruments (traditional XRF) take their measurement from the bottom of the sample, settling occurs at the focal point of the analysis rendering the analyzer’s automatic interference correction, ineffective. To prevent biased results, many laboratories centrifuge all crude oil samples prior to analysis by traditional D4294 instruments. This increases the amount of processing and time it takes to perform the measurement.

SOLUTION

Many D4294 analyzers are designed with the X-ray detector focused on the bottom of a sample cup where settling occurs, as depicted in Diagram 1. Since particulate solids and water settle over time, it is difficult to obtain accurate sulfur measurements due to the changing concentration of interferences. To combat the effects of settling in crude oil, Petra MAX delivers a new, innovative sample chamber that rotates the sample on its side, providing a clear measurement window for more accurate results. See Diagram 2.

SAMPLE INTRODUCTION METHODS

Diagram 1: Traditional XRF

Diagram 2: Petra MAX

INTERFERENCE STUDIES

To evaluate the effects of interfering elements, crude oil samples were obtained from three North American refineries. The samples were received in five-gallon drums and then stored in one-liter containers. The iron concentration for each sample was used to estimate the degree of interference. Table 1 shows a summary of the iron concentration and level of particulate settling for each sample.

| Table 1: Crude Oil Classification | ||

|---|---|---|

| Iron (ppm) | Particulate Settling | |

| Crude A | 35 | High |

| Crude B | 8 | Medium |

| Crude C | 2 | Low |

TRADITIONAL XRF VS. PETRA MAX

To study the effects of particulate solids on sulfur measurements, a crude oil sample was analyzed using a traditional XRF analyzer and Petra MAX. Refer to Diagrams 1 and 2 for sample introduction methods. The following sample analysis procedure was performed using both methods:

- A particulate-free certified reference standard of 2 wt% S in mineral oil sample was measured for 100-seconds to check instrument accuracy

- One-liter bottles of crude oil were shaken vigorously, and samples were prepared and measured immediately for 100-seconds

Measurements were repeated 5 times with a 5-second pause in-between. The data was collected and compiled to evaluate the effect of particulate settling on sulfur analysis.

Note: Organosulfur compounds are homogeneous in the sample. Particulates represent elements like Ca, Cl, and Fe.

RESULTS

2% S in Mineral Oil – No Particulates

In order to test the accuracy of each sample introduction method, a particulate-free certified reference standard of 2% sulfur in mineral oil sample was analyzed using both traditional XRF and Petra MAX. Results for both methods demonstrate excellent accuracy. No particulates were present, and all measurements were within 1% of the known sulfur value and met the repeatability requirements for ASTM D4294 and ISO 8754. These results show that in the absence of particulate settling, both sample introduction methods provide accurate results.

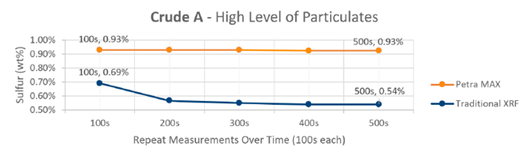

Graph 1: Crude A Results

Crude A - High Level of Particulates

Results for Crude A, containing a high level of particulates, are shown in Graph 1. While the traditional XRF results show a rapid drift in sulfur concentration due to particulate settling, the results from Petra MAX remain stable for each repeat measurement. This demonstrates that, even with high levels of particulates, Petra MAX delivers accurate and precise sulfur measurements in crude oil for ASTM D4294 and ISO 8754 methodology

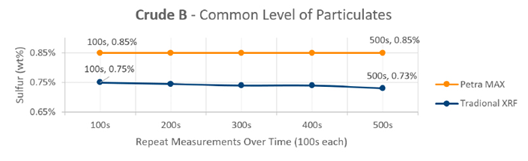

Graph 2: Crude B Results

Crude B - Medium Level of Particulates

The results for Crude B, containing a medium (common) level of particulates, are shown in Graph 2. In this crude oil sample, the drift in sulfur concentration for traditional XRF analysis is much less than in Crude A. However, there is a 12% lower sulfur concentration reported by the traditional XRF analysis than Petra MAX, demonstrating that even medium levels of particulate settling still impact the reported sulfur concentration. Petra MAX delivers stable results over the five repeat measurements of Crude B.

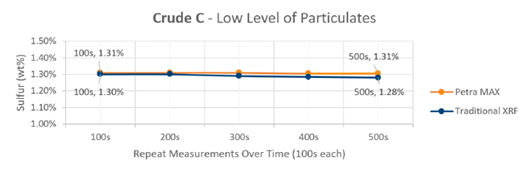

Graph 3: Crude C Results

Crude C - Low Level of Particulates

The results for Crude C, containing a low level of particulates, are shown in Graph 3. These results demonstrate that when particulate settling is low, both the traditional XRF and Petra MAX methods show agreement in reported sulfur concentration. This confirms that particulate settling is the cause for underreported sulfur concentrations with traditional XRF analysis.

RESULTS SUMMARY

Table 2 below shows a summary of the total sulfur drift results of all three crude oil samples from the first to the fifth 100-second measurement, after sitting for 500-seconds. Results from the particulate-free reference standard samples are also included.

| Table 2: Total Sulfur Drift Results – Petra MAX vs. Traditional XRF | ||||||||

|---|---|---|---|---|---|---|---|---|

| CRUDE A High Level of Particulates | CRUDE B Medium Level of Particulates | CRUDE C Low Level of Particulates | 2% S in Mineral Oil No Particulates | |||||

| Repeats (100s) | Petra MAX | Traditional XRF | Petra MAX | Traditional XRF | Petra MAX | Traditional XRF | Petra MAX | Traditional XRF |

| #1 | 0.930 | 0.690 | 0.850 | 0.751 | 1.304 | 1.301 | 2.010 | 1.995 |

| #5 | 0.925 | 0.541 | 0.848 | 0.734 | 1.305 | 1.285 | 2.012 | 1.989 |

| % Drift | 0.5% | 21.6% | 0.2% | 2.3% | -0.1% | 1.2% | -0.1% | 0.3% |

| All values for Sulfur in wt% | ||||||||

When comparing the results for the particulate-free certified reference sample (2% S in Mineral Oil) between Petra MAX and traditional XRF, there is no drift or bias present. When comparing results for the Crude A sample, there is a significant difference in the reported sulfur concentration. In the initial measurement (repeat #1) for Crude A, the traditional XRF analysis reported 26% less sulfur than Petra MAX. This demonstrates that even if samples were prepared and measured quickly, traditional methods still significantly underreport the sulfur concentration. After the fifth measurement (repeat #5) for Crude A, the traditional XRF analysis reported 42% less sulfur than Petra MAX.

CONCLUSION

In conclusion, crude oil samples with medium to high levels of particulate solids may cause a matrix effect interference of the sulfur signal with traditional XRF when using ASTM D4294 and ISO 8754 methodology. Because settling can happen very quickly, even rapid sample preparation and measurement cannot prevent underreported sulfur in crude oils that exhibit particulate settling.

Increased availability of crude oils with properties at the extreme end of the API scale, like light shale oils and heavy crude from oil sands, has increased the blending of crude oils in order to attain desirable properties that match refinery operating requirements. This study demonstrates that matrix effects from particulate settling can affect reported sulfur results by as much as 40% in traditional D4294 analysis, which will likely lead to misclassifying sweet and sour crude oil.

The new Petra MAX sample introduction technique eliminates the matrix effects altogether, and offers a more efficient process compared to centrifuge pretreatment. As demonstrated throughout this study, Petra MAX delivers stable results regardless of the level of particulates in the crude oil.