- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Energy Dispersive X-ray Fluorescence (EDXRF)

Energy Dispersive X-ray Fluorescence (EDXRF) is one of two general types of X-ray Fluorescence techniques used for elemental analysis applications. In EDXRF spectrometers, all of the elements in the sample are excited simultaneously, and an energy dispersive detector in combination with a multi-channel analyzer is used to simultaneously collect the fluorescence radiation emitted from the sample and then separate the different energies of the characteristic radiation from each of the different sample elements. Resolution of EDXRF systems is dependent upon the detector, and typically ranges from 150 eV – 600 eV. The principal advantages of EDXRF systems are their simplicity, fast operation, lack of moving parts, and high source efficiency.

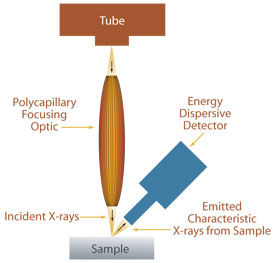

X-ray optics can be used to enhance EDXRF instrumentation. For conventional XRF instrumentation, typical focal spot sizes at the sample surface range in diameter from several hundred micrometers up to several millimeters. Polycapillary focusing optics collect X-rays from the divergent X-ray source and direct them to a small focused beam at the sample surface with diameters as small as tens of micrometers. The resulting increased intensity delivered to the sample in a small focal spot allows for enhanced spatial resolution for small feature analysis and enhanced performance for measurement of trace elements for Micro EDXRF applications.

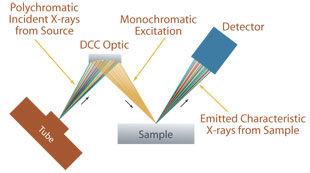

Doubly curved crystal optics direct an intense micron-sized monochromatic X-ray beam to the sample surface for enhanced elemental analysis.