- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Precision Comparison Case Study — Petra MAX (EDXRF®) vs ICP (IP 501 & IP 621)

Background

As petroleum professionals continue to refine their production processes, products such as crude oil, residual fuel oils, and VGO can contain higher concentrations of problematic metals like nickel (Ni), iron (Fe), and vanadium (V). In the face of tightening regulations and increased demand for sweeter crudes, refiners are looking to buy lower-cost oils that contain these metals, with the intent of assessing their concentration levels throughout the refining process.

The reason these metals need to be continually monitored is due to their problematic effects on refining processes. For example, nickel and iron rapidly deactivate process catalysts used in hydrotreaters and FCC units, which leads to offspecification coke and increased, unplanned costs to refiners. To compound the challenge of attaining a sweet crude and mitigating the risk of damage from metals, refineries, and other petroleum certification sites, such as terminals and thirdparty labs, must adhere to regulations that might require them to utilize IP 501 and IP 621 methodology. There is, however, an option for users to screen samples before ICP using XRF (X-ray fluorescence) analysis or to supplement their wet chemistry procedures with the use of XRF to further improve their processes.

As mentioned, there are two well-known technologies for elemental analysis: X-ray fluorescence (XRF in various methods and forms such as energy-dispersive XRF (EDXRF) or wavelength-dispersive XRF (WDXRF)) and wet chemistry (ICP and AAS), which includes methods such as IP 501 and IP 621. With IP 501 and IP 621, samples must first go through a time-consuming and sensitive sample preparation process which involves breaking down the sample, mixing it with other materials, digesting it in acid, and then diluting it in water. Only after this lengthy and complicated process is the sample then measured with either ICP OES (IP 501) or ICP-OES/AAS (IP 621). Both methods are considered highly precise, however, not only do they typically take 4-10 hours to complete, but due to the multiple complex steps, they require specially trained operators. In addition, the multiple steps may increase the likelihood for variability within the process and negatively impact precision.

BETTER PRECISION WITH EDXRF®

XRF analysis involves exposing the sample to X-rays in order to produce an emission at an energy level that is characteristic of the element of interest. This method involves minimal sample preparation and provides results within minutes. EDXRF is one of the more well-known forms of XRF technology. High Definition X-ray Fluorescence (EDXRF®), XOS’ patented technology, is an improved version of the EDXRF technique that applies state-of-the-art monochromating optics, enabling a dramatically higher signal-to-background ratio. This technique also reduces background noise, delivering lower limits of detection and significantly better precision at even lower concentration levels.

XRF analysis involves exposing the sample to X-rays in order to produce an emission at an energy level that is characteristic of the element of interest. This method involves minimal sample preparation and provides results within minutes. EDXRF is one of the more well-known forms of XRF technology. High Definition X-ray Fluorescence (EDXRF®), XOS’ patented technology, is an improved version of the EDXRF technique that applies state-of-the-art monochromating optics, enabling a dramatically higher signal-to-background ratio. This technique also reduces background noise, delivering lower limits of detection and significantly better precision at even lower concentration levels.

CHALLENGE

While professionals in the petroleum industry might be more familiar with IP 501 and IP 621 or feel they need to adhere to these methods in particular, those looking to reduce downtime during the process may consider a cost-effective, faster, in-house alternative. Some labs may have the luxury 2 of running these wet chemistry methods inhouse, but many professionals, such as those working at terminals, pipelines, and smaller labs, may have to send samples out for testing. This not only results in higher costs, but more importantly, significant turnaround time for the data—which can occasionally result in increased downtime when products come back from IP 501/621 analysis as being out of spec. By testing in-house and getting results in less than five minutes, refineries, terminals, and labs will be able to make real-time decisions based on the faster availability of that data.

SOLUTION

Petra MAX, powered by EDXRF®, can be used as a cost-effective screening tool, enabling users to pre-screen their samples before sending them out for wet chemistry testing and make critical decisions faster. Likewise, even those with access to in-house ICP/ AAS processes can save hours of sample preparation time by first screening the samples with Petra MAX, then running off-spec or near off-spec with wet chemistry.

CASE STUDY

Recently, a large European refinery was interested in testing the performance of Petra MAX as a potential addition to their in-house testing process, as they saw great value in obtaining Ni, V, and Fe results in under 5 minutes. This refinery performed an elemental analysis study comparing the precision performance between Petra MAX (EDXRF®) and ICP (IP 501 and IP 621) with VGO and fuel oils. In this paper, we will review the study performed and discuss the data provided by the refinery.

TESTING PRECISION

The refinery prepared and measured 10 different VGO samples both on Petra MAX and with IP 621 for Ni, V, and Fe. A second set of 10 fuel oil samples were also run on Petra MAX as well as with IP 501 for Ni and V, in addition to a single sample for Fe. The samples run on Petra MAX were measured for a 5-minute measurement time, with sample preparation limited to pouring 7-8 ml into a sample cup and applying the sample film.

| Table 1: Iron in VGO Samples Between Petra MAX and IP 621 | |||

|---|---|---|---|

| Element: Iron Sample Type: VGO |

Petra MAX Results in mg/kg |

ICP Method IP 621 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 0.53 | 0.30 | 0.23 |

| Sample 2 | 0.65 | 0.47 | 0.18 |

| Sample 3 | 0.99 | 0.80 | 0.19 |

| Sample 4 | 0.22 | 0.50 | 0.28 |

| Sample 5 | 0.71 | 0.30 | 0.41 |

| Sample 6 | 0.83 | 0.40 | 0.43 |

| Sample 7 | 0.20 | 0.20 | 0.00 |

| Sample 8 | 0.28 | 0.10 | 0.18 |

| Sample 9 | 0.16 | 0.10 | 0.06 |

| Sample 10 | 0.17 | 0.20 | 0.03 |

| Table 2: Nickel in VGO Samples Between Petra MAX and IP 621 | |||

|---|---|---|---|

| Element: Nickel Sample Type: VGO |

Petra MAX Results in mg/kg |

ICP Method IP 621 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 0.19 | 0.16 | 0.03 |

| Sample 2 | 0.39 | 0.37 | 0.02 |

| Sample 3 | 0.52 | 0.50 | 0.02 |

| Sample 4 | 0.12 | 0.10 | 0.02 |

| Sample 5 | 0.24 | 0.20 | 0.04 |

| Sample 6 | 0.12 | 0.10 | 0.02 |

| Sample 7 | 0.14 | 0.10 | 0.04 |

| Sample 8 | 0.30 | 0.20 | 0.10 |

| Sample 9 | 0.31 | 0.23 | 0.08 |

| Sample 10 | 0.19 | 0.32 | 0.13 |

| Table 3: Vanadium in VGO Samples Between Petra MAX and IP 621 | |||

|---|---|---|---|

| Element: Vanadium Sample Type: VGO |

Petra MAX Results in mg/kg |

ICP Method IP 621 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 0.50 | 0.33 | 0.17 |

| Sample 2 | 0.86 | 0.80 | 0.06 |

| Sample 3 | 1.07 | 1.10 | 0.03 |

| Sample 4 | 0.43 | 0.30 | 0.13 |

| Sample 5 | 0.21 | 0.10 | 0.11 |

| Sample 6 | 0.37 | 0.20 | 0.17 |

| Sample 7 | 0.25 | 0.20 | 0.05 |

| Sample 8 | 0.31 | 0.30 | 0.01 |

| Sample 9 | 0.13 | 0.10 | 0.03 |

| Sample 10 | 0.57 | 0.56 | 0.01 |

| Table 4: Iron in VGO Samples Between Petra MAX and IP 501 | |||

|---|---|---|---|

| Element: Iron Sample Type: Fuel Oil |

Petra MAX Results in mg/kg |

ICP Method IP 501 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 64.87 | 64.00 | 0.87 |

| Table 5: Nickel in VGO Samples Between Petra MAX and IP 501 | |||

|---|---|---|---|

| Element: Nickel Sample Type: Fuel Oil |

Petra MAX Results in mg/kg |

ICP Method IP 501 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 56.33 | 51 | 5.33 |

| Sample 2 | 33.98 | 30 | 3.98 |

| Sample 3 | 43.02 | 39 | 4.02 |

| Sample 4 | 19.14 | 17 | 2.14 |

| Sample 5 | 57.74 | 51 | 6.74 |

| Sample 6 | 20.42 | 18 | 2.42 |

| Sample 7 | 52.37 | 47 | 5.37 |

| Sample 8 | 59.11 | 54 | 5.11 |

| Sample 9 | 21.99 | 20 | 1.99 |

| Table 6: Vanadium in VGO Samples Between Petra MAX and IP 501 | |||

|---|---|---|---|

| Element: Vanadium Sample Type: Fuel Oil |

Petra MAX Results in mg/kg |

ICP Method IP 501 Results in mg/kg |

Difference in mg/kg |

| Sample 1 | 256.75 | 255 | 1.75 |

| Sample 2 | 199.77 | 204 | 4.23 |

| Sample 3 | 64.84 | 64 | 0.84 |

| Sample 4 | 129.48 | 127 | 2.48 |

| Sample 5 | 15.95 | 15 | 0.95 |

| Sample 6 | 135.86 | 134 | 1.86 |

| Sample 7 | 41.00 | 40 | 1 |

| Sample 8 | 106.43 | 108 | 1.57 |

| Sample 9 | 192.20 | 186 | 6.2 |

| Sample 10 | 25.19 | 25 | 0.19 |

COMPARING PRECISION BETWEEN EDXRF® AND ICP DATA FROM ASTM PTP STUDY

In a recently published whitepaper, we compared the precision of EDXRF® to ASTM D5708B, a common Inductively Coupled Plasma (ICP) method for the determination of nickel, vanadium, and iron in crude and residual fuel oils. The ICP data was obtained from an ASTM Proficiency Testing Program (PTP). This data demonstrated that EDXRF® (Petra MAX) delivers comparable results to ICP but can be obtained much faster – in five minutes or less. Visit xos.com/petroleum/precision-comparison-for-ni-fe-v to view this whitepaper.

In a recently published whitepaper, we compared the precision of EDXRF® to ASTM D5708B, a common Inductively Coupled Plasma (ICP) method for the determination of nickel, vanadium, and iron in crude and residual fuel oils. The ICP data was obtained from an ASTM Proficiency Testing Program (PTP). This data demonstrated that EDXRF® (Petra MAX) delivers comparable results to ICP but can be obtained much faster – in five minutes or less. Visit xos.com/petroleum/precision-comparison-for-ni-fe-v to view this whitepaper.

DID YOU KNOW?

In addition to providing easy, highly precise and accurate results for Ni, V, and Fe, as well as nine other elements, Petra MAX complies with ISO 8754 and ASTM D4294 for sulphur all in one measurement —an even greater time savings for petroleum labs.

RESULTS

As shown in Tables 1, 2 and 3 for VGO, and Tables 4, 5, and 6 for fuel oil, the results of Petra MAX compare quite favorably to that of the ICP methods (IP 501 and IP 621) between the two different sample types and across multiple element concentrations and measurements. The differences between the Petra MAX results and the IP 501 and IP 621 results are all well within reproducibility for those methods and in almost all cases, even with repeatability, are great indicators of comparable accuracy. Given its minimal sample preparation, rapid 5-minute results and ease of use, Petra MAX is a valuable tool for industry professionals to determine Ni, V, and Fe concentrations in VGO and fuel oils.

CONCLUSION

Petra MAX, powered by EDXRF, delivers comparable results to IP 501 and IP 621 in five minutes or less. In addition, users have minimal sample preparation and can achieve results with the push of a button. Those looking to save time and money in elemental quantification by screening samples before ICP analysis can achieve comparable results with Petra MAX.

This study resulted in the refinery purchasing Petra MAX—a decision that has since saved them significant sample preparation and testing time while simultaneously reducing turnaround time for metal and sulphur analyses.

Author:

Satbir Nayar,

Sr. Product Manager, Petroleum

Author:

Julian Doug van Berkum,

Technical Sales & Applications Specialist

Petra MAX delivers advanced elemental analysis powered by EDXRF, utilizing XOS patented doubly curved crystal optics coupled with a high-performance silicon drift detector and an intense monochromatic excitation beam. This industry leading technology reduces background noise and increases signal-to-noise output, enabling low detection limits and high precision. Petra MAX offers low-level detection of iron, saving the marine industry money on engine replacement and lube oil costs, while also using a next-generation interface that saves users time.

Petra MAX Autosampler delivers a more efficient workflow with sample tracking and continuous sample loading. Typical XRF benchtop automatic sampler systems, often known as a “carousel”, require users to manually enter each sample name into the system. This can result in data errors and in turn, rework. In addition, once the carousel has been loaded, it cannot be interrupted until the analyser has finished analysis. This is not an ideal process for third-party test labs who work in a fast-paced environment and often receive urgent sample requests. With the new Petra Series Autosampler, users simply scan the QR-coded sample cup with a handheld scanner and the analyser scans the sample again when it reaches the measurement chamber, ensuring the correct sample name and measurement parameters are paired with results. Users can eliminate data errors and add urgent samples to the queue as needed. The Autosampler is an optional add-on feature and users have the option to use X-ID Sample Cups (QR-coded) or standard XRF cups.

A UNIQUE SAMPLE INTRODUCTION SYSTEM TO ELIMINATE CENTRIFUGE

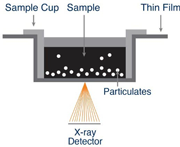

Particulate solids and water have shown to cause underreported sulphur measurements by as much as 40%. Such a significant error can cause misclassification of sour crude oil as sweet crude oil. With global regulatory trends lowering sulphur levels in refined products from diesel to marine fuel, underreporting sulphur may cause refiners to miscalculate the costs associated with processing incoming crude oil. Many D4294 analyser are designed with the X-ray detector focused on the bottom of a sample cup where settling occurs, as depicted in Diagram 1. Since particulate solids and water settle over time, it is difficult to obtain accurate sulphur measurements due to the changing concentration of interferences.

Because traditional D4294 XRF instruments take their measurement from the bottom of the sample, settling occurs at the focal point of the analysis rendering the analyser’s automatic interference correction, ineffective. To prevent biased results, many laboratories centrifuge all crude oil samples prior to analysis by traditional D4294 instruments. This increases the amount of processing and time it takes to perform the measurement.

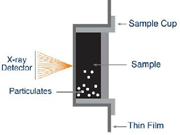

To combat the effects of settling in crude oil, Petra MAX delivers a new, innovative sample chamber that rotates the sample on its side, providing a clear measurement window for more accurate results. See Diagram 2.

Diagram 1: Traditional XRF

Diagram 2: Petra MAX™

NEW GEN 4 SOFTWARE OFFERS AN ADVANCED WORKFLOW

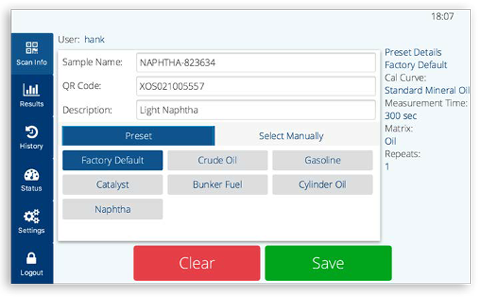

The new Gen 4 software upgrade for Petra Series offers novel features for a simple, intuitive operation, including preset measurement configurations, streamlined custom calibration setup, enhanced LIMS compatibility, and additional matrices like water and catalysts.

To match the expanding measurement capabilities of Petra Autosampler, users will now be able to set unique preset measurements with adjustable parameters for quick access to pre-determined measurement types. For example, a terminal frequently running crude oil samples can set a c rude oil preset which includes a 300s measurement time, a preselected matrix type and calibration curve, and a default number of sample repeats (see Figure 1). Additionally, this preset can be set as the default measurement. The presets can be set directly after users scan their QR-coded cup or sample bottle with a single push of a button before loading the sample into the analyser. All this information can be found on the main scan screen to reinforce the high throughput and efficient workflow that Petra offers.

Once a sample begins its measurement, live results will begin to populate for the elements of interest. Users can continue to load samples, work with a different instrument, or view their historical results. When a sample is not being measured, completed measurements can be averaged on-screen using the built-in averaging function. When running repeats, results will be automatically averaged and viewable as a separate file without the need to export data. Those looking to export their data can do so either through their network, USB drive, or as a printable CSV or PDF.