- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Transmix Reduction with Rapid Sulfur Monitoring

BACKGROUND...

Effective Online Sulfur Analysis in Petroleum Process Streams

Sindie® Online is an industrial grade process sulfur analyzer with breakthrough detection capability to monitor ultra low sulfur in petroleum or aqueous process streams. This process analyzer presents the ultimate solution for refineries and pipeline terminals where measurement speed and reliability are essential. Powered by MWDXRF®, Sindie Online uses ASTM D7039 technology and delivers real-time, continuous analysis of total sulfur from 0.5 ppmw up to 3000 ppmw. This process analyzer is ATEX and NEC certified for hazardous area locations.

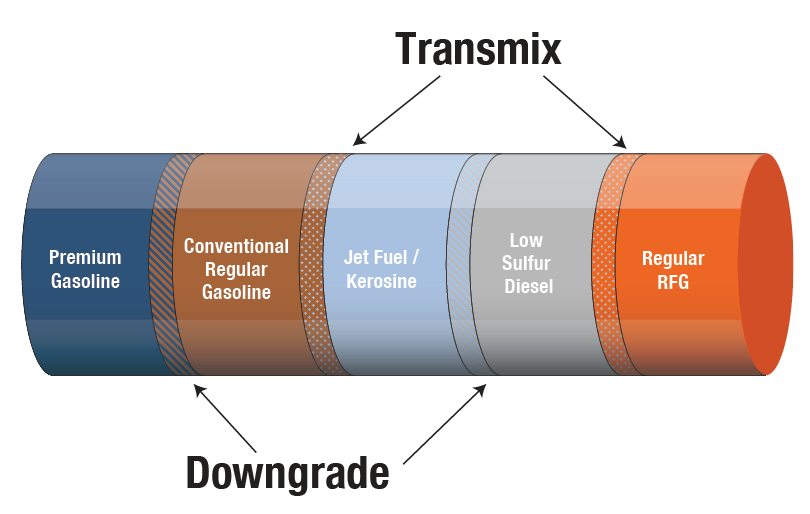

Many different types and grades of petroleum products travel through pipelines in batches. Some mixing occurs at the interface between batches which results in transmix generation and product downgrading as shown in Figure 1. Transmix is the portion of the pipeline flow that is diverted to a separate tank to avoid contamination between two dissimilar product batches. Transmix generates millions of dollars in costs to shippers and pipeline operators. These costs occur because the transmix must be stored, transported, and reprocessed to decontaminate and separate the mixed products. Product downgrade or regrade happens when a portion of higher value, but mixable product, is diverted to a tank that holds a batch of lower value product, such as premium gasoline being diverted to a regular gasoline tank. The higher value product batch is protected from contamination, but a portion is downgraded to the lower value product, resulting in a loss of value equal to the difference in price between the two products.

Many pipelines have made investments to automate their batch cutting procedures in order to reduce the amount of transmix generated. By optimizing the batch cut timing through automation, they can reduce the amount of product sent to the transmix tank. An important component of the automation process is the integration of an online analyzer. The online analyzer is used to identify, in real-time, when the interface between products has been moved to the transmix tank. Any unique parameter between the products can be used to make this determination. A common parameter used for this application is specific gravity. When the products on each side of the interface have distinct densities, an accurate cut can occur and minimize the amount of transmix or downgraded product generated - resulting in considerable cost savings. Table 1 depicts the specific gravity range by product.

| Table 1: Specific Gravity Range by Product | ||

|---|---|---|

| Product | Min Specific Gravity | Max Specific Gravity |

| Gasoline | 680 g/L | 740 g/L |

| Jet Fuel | 775 g/L | 840 g/L |

| Diesel Fuel | 810 g/L | 960 g/L |

In some situations, the specific gravity range may overlap between products. In this case, you can use sulfur as a parameter to determine when to make a batch cut. Regulations, such as Ultra Low Sulfur Diesel and Tier 3 Gasoline, have set sulfur limits at 15 ppm and 10 ppm respectively, and even a small amount of product like jet fuel containing up to 3,000 ppm sulfur can contaminate a large batch of low sulfur product.

Sindie Online is an industrial-grade process sulfur analyzer designed for continuous sulfur testing to facilitate more precise fuel interface cuts in order to reduce transmix and prevent tank contamination. By using a unique X-ray focusing technology, Sindie Online delivers real-time, continuous sulfur measurements to provide rapid feedback for batch cut decisions. With a dynamic range from 0.5 ppm to 3000 ppm, and an extended range to percent levels, this instrument can measure sulfur in ultra low sulfur products.

METHODOLOGY

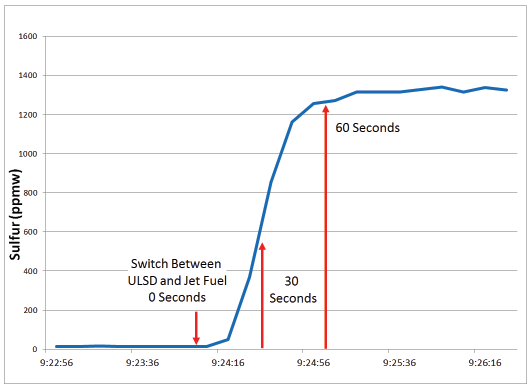

To demonstrate the rapid sensing capabilities of Sindie Online, a stream of Ultra Low Sulfur Diesel (ULSD) with 13 ppm sulfur was introduced to the measurement system. The analyzer was configured to update results every 10 seconds. While it continued to take measurements, the sample stream to the analyzer was switched to jet fuel with 1,350 ppm sulfur content. The sulfur levels are shown in Figure 2.

Figure 2: Real-time Interface Identification by Sindie Online

Sindie Online identifies the change within 10 seconds and detects new equilibrium at 60 seconds

CONCLUSION

This application brief demonstrates that Sindie Online is a viable solution to identify the interface between products - fast enough to allow for precision cuts of pipeline batches and therefore reduce downgraded product and transmix generation. This can help pipeline operators save millions of dollars annually.

ADVANCED ANALYSIS WITH MWDXRF

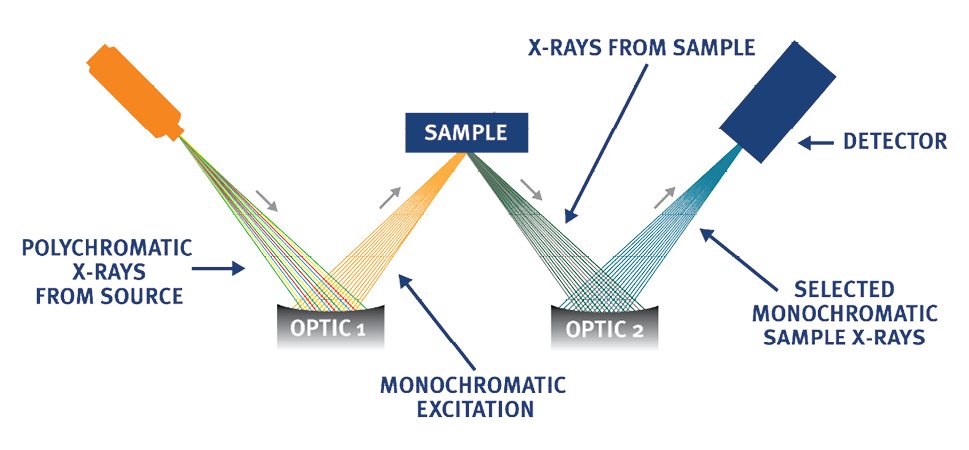

Monochromatic Wavelength Dispersive X-ray Fluorescence (MWDXRF) utilizes state-of-the-art focusing and monochromating optics to increase excitation intensity and dramatically improve signal-to-background ratio compared to traditional WDXRF instruments. This enables significantly improved detection limits, precision, and a reduced sensitivity to matrix effects. A monochromatic and focused primary beam excites the sample and secondary characteristic fluorescence X-rays are emitted from the sample. A second monochromating optic selects the sulfur characteristic X-rays and directs these X-rays to the detector. MWDXRF is a direct, non-destructive measurement technique and does not require consumable gasses or sample conversion delivering robust and low maintenance analyzers with dramatically lower detection limits and faster response times.

MWDXRF Technology