- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Certifying Sulfur in Automotive Fuels & Monitoring Chlorine for Corrosion Mitigation

Print

Abstract

With the high volatility in crude prices leading to uncertainty in budgets, refiners are seeking new, innovative ways to respond to the industry’s dynamic landscape. Refineries are facing many new challenges, including complying with new regulations, protecting against chlorine-induced corrosion, and the costs associated with both.

- Globally, adoption of regulations like Euro VI and Tier 3 continue to lower the required sulfur level in automotive fuels. With these changes come challenges, and it is more important than ever to seek out the most precise and reliable solution to produce the best data.

- Refinery corrosion is a critical and very expensive problem. Leading refiners have found that by lowering the chloride content of desalted crude oil and process streams, they can significantly extend time between turnarounds, lower the costs of corrosion, and decrease related safety hazards.

Application Study

1. Certifying Sulfur in Automotive Fuels

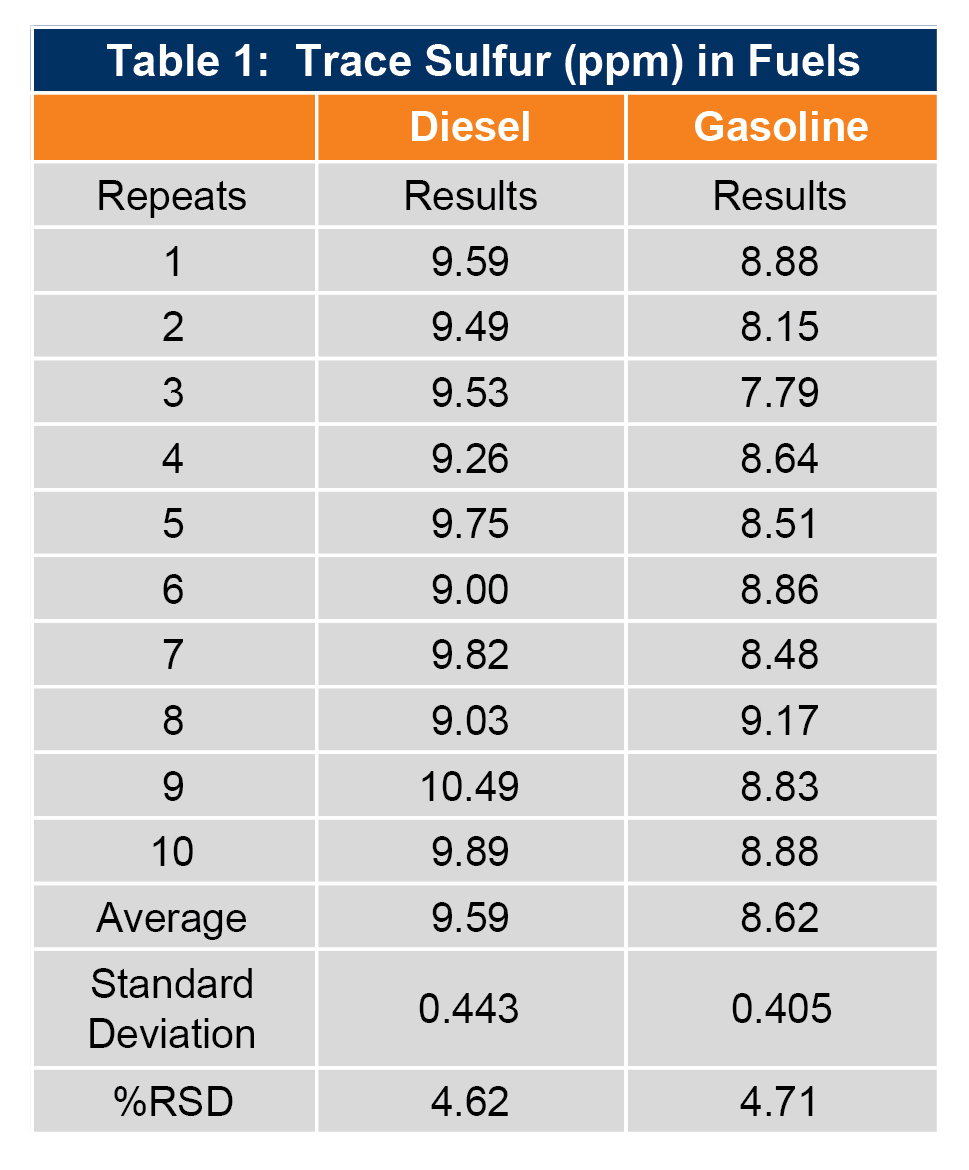

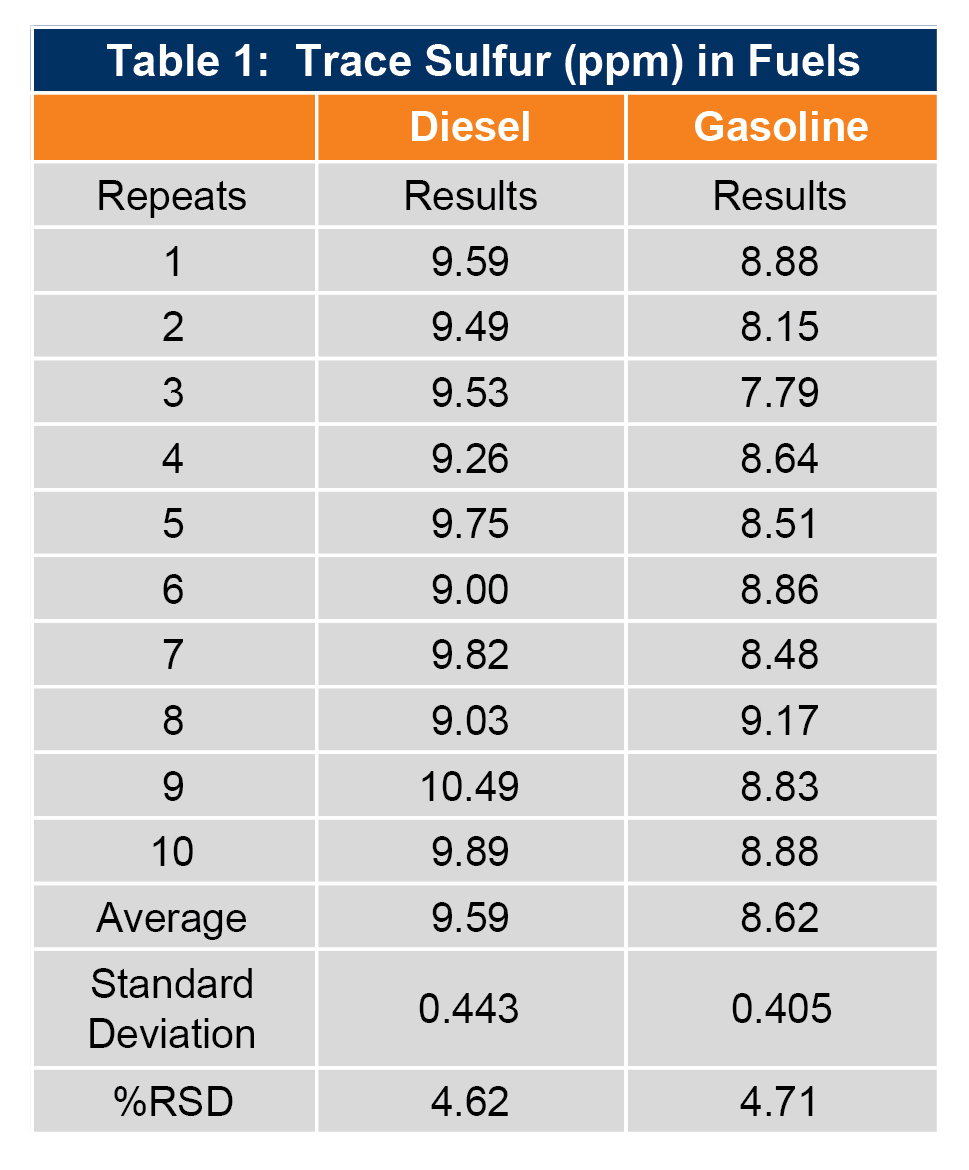

MWDXRF has long been in the petroleum industry for certification of sulfur levels in diesel and gasoline blends. To study the performance of Sindie +Cl, ten repeat measurements were performed on commerciallyavailable diesel and gasoline standards with 10 ppm and 9 ppm sulfur respectively. Ten separate aliquots of each of the diesel and gasoline samples were measured for five minutes each using ASTM D7039 methodology. The result of ten measurements on a 10 ppm sulfur in diesel standard was an average value of 9.59 ppm sulfur, with a standard deviation of 0.44 ppm, and a relative standard deviation (RSD) of 4.62%. The results of the ten measurements on the 9 ppm sulfur in gasoline standard was an average of 8.62 ppm, 0.41 ppm standard deviation, and 4.71% RSD. Additionally, as outlined in the ASTM D7039 method, if the repeats are paired (i.e. 1 and 2, 3 and 4, etc.), each paired repeat is within the method’s repeatability standard. The measurement data for this study can be seen in Table 1.

2. Monitoring Chlorine for Corrosion Mitigation

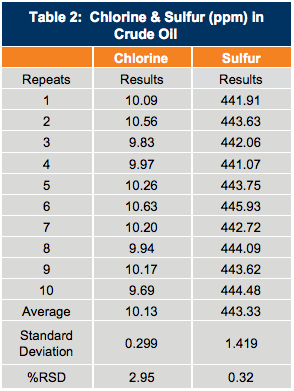

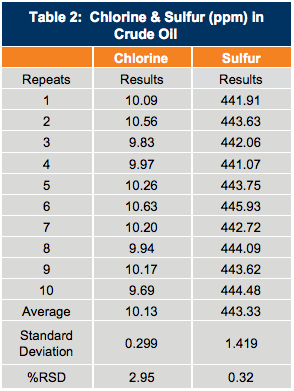

In an effort to mitigate the multi-billion dollar costs of corrosion in global refineries, the regular monitoring of chlorine in desalted crude oil is becoming more critical. To assess the performance of Sindie +Cl for this application, ten repeat measurements were performed on a commercially available 10 ppm chlorine in crude oil standard. The sulfur content of this standard was unknown. Ten separate aliquots of the crude oil were measured simultaneously for chlorine and sulfur using a five-minute measurement time. A modified D7536 procedure was used for chlorine measurements, which included a 0-500 ppm chlorine in mineral oil calibration for the measurement of crude oil. Results of the ten chlorine measurements averaged 10.13 ppm chlorine, with a standard deviation of 0.30 ppm, and a 2.95% RSD. Despite the modified chlorine procedure, if the repeats are paired (i.e. 1 and 2, 3 and 4, etc.), each paired repeat is within D7536 repeatability. For the sulfur values, results averaged 443.33 ppm, with a standard deviation of 1.42 ppm, and an RSD of 0.32%. Paired repeat measurements exhibit precision within ASTM D2622 repeatability. The measurement data for this study can be seen in Table 2.

3. Automatic Sulfur Correction

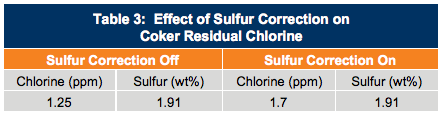

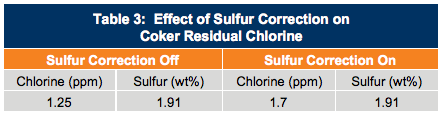

Many heavy samples, like crude oil, VGO or coker residual, may have percentlevel sulfur present while chlorine may be as low as a few parts per million. High sulfur levels will typically depress the chlorine measurement result during XRF analysis. Sindie +Cl is able to measure the sulfur and chlorine concentrations simultaneously and then automatically correct the chlorine measurement. To illustrate this issue, a coker residual sample was first analyzed for chlorine and sulfur with the automatic sulfur correction disabled, and then the sample was reanalyzed with the automatic sulfur correction enabled to demonstrate this capability. This comparison can be seen in Table 3, where the use of automatic sulfur correction will assist in the prevention of reporting falsely low measurement results.

Apparatus

Sindie +Cl utilizes a technique known as Monochromatic Wavelength Dispersive X-ray Fluorescence (MWDXRF) - delivering exceptional reproducibility. It delivers both sulfur and chlorine trace analysis with one push of a button and zero hassle. Samples are measured directly, which means it can analyze even the heaviest of hydrocarbons like crude oil or coker residuals, without the hassle of boats, injectors, furnaces, or changing detectors.

Method Compliance

- ASTM D2622, D7039, D7536

- SH / T 0842e

Conclusion

The results of this application study demonstrate that Sindie +Cl is an ideal solution for multiple applications where precision, ease-of-use, and flexibility is needed. Get Sindie +Cl to certify low sulfur level fuels for regulatory purposes, and monitor chlorine in desalted crudes and other process streams to identify potential sources of corrosion.