- Analyzers

- Optics & Sources

- Technologies

- Support

- About

X-Ray Fluorescence (XRF)

What is XRF

X-ray fluorescence (XRF) is a powerful quantitative and qualitative analytical tool for elemental analysis of materials. It is ideally suited to the measurement of film thickness and composition, determination of elemental concentration by weight of solids and solutions, and identification of specific and trace elements in complex sample matrices. XRF analysis is used extensively in many industries including semiconductors, telecommunications, microelectronics, metal finishing and refining, food, pharmaceuticals, cosmetics, agriculture, plastics, rubbers, textiles, fuels, chemicals, and environmental analysis. The method is fast, accurate, non-destructive, and usually requires only minimal sample preparation.

How XRF works

When elements in a sample are exposed to a source of high intensity X-rays, fluorescent X-rays will be emitted from the sample at energy levels unique to those elements.

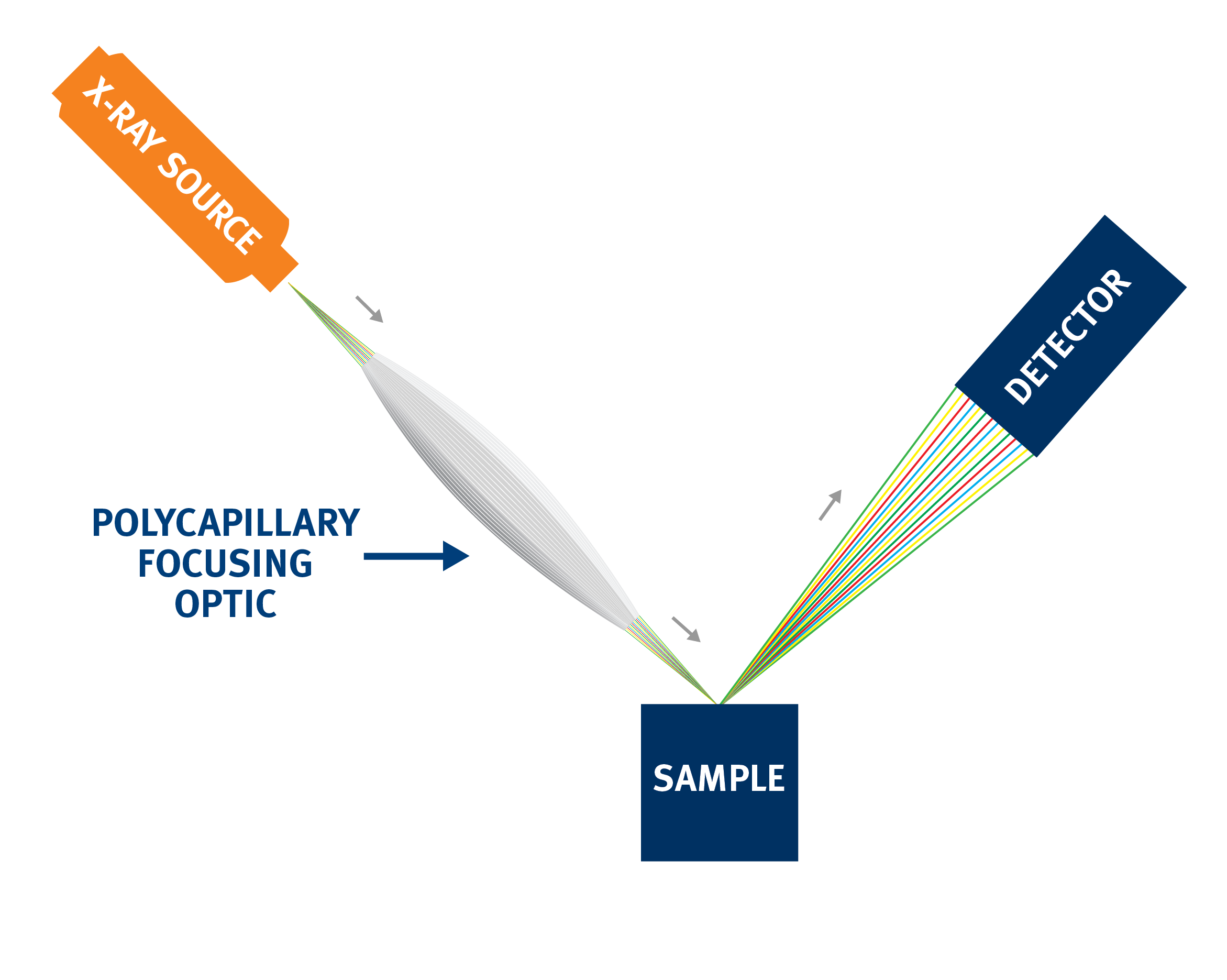

The basic concept for all XRF spectrometers is a source, a sample, and a detection system. The source irradiates the sample and a detector measures the fluorescence radiation emitted from the sample. In most cases for XRF, the source is an X-ray tube. Alternatives are a radioactive source or a synchrotron. There are two main types of XRF instruments: Energy Dispersive X-ray fluorescence (EDXRF)and Wavelength Dispersive X-ray Fluorescence (WDXRF).

X-ray optics can be used to enhance both types of XRF instrumentation. For conventional XRF instrumentation, typical focal spot sizes at the sample surface range in diameter from several hundred micrometers up to several millimeters. Polycapillary focusing optics collect X-rays from the divergent X-ray source and direct them to a small focused beam at the sample surface with diameters as small as tens of micrometers. The resulting increased intensity, delivered to the sample in a small focal spot, allows for enhanced spatial resolution for small feature analysis and enhanced performance for measurement of trace elements for Micro X-ray Fluorescence applications. Doubly curved crystal optics direct an intense micron-sized monochromatic X-ray beam to the sample surface for enhanced elemental analysis.