- Analyzers

- Optics & Sources

- Technologies

- Support

- About

Parallel Beam Geometry XRD for Stress and Strain Measurements

Stress or stain in a material can cause visible changes in the diffraction pattern of a material. These changes are observed as diffraction peak asymmetry, peak broadening, or peak shifting. The diffraction pattern of a material can be monitored during fabrication or manufacturing to see if these processes are causing any unwanted stress or stain in the material. Discrete samples can be monitored periodically during an industrial process, or diffraction can be measured on-line during sample processing.

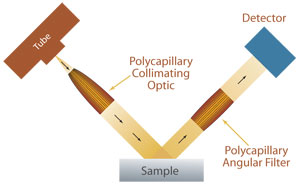

X ray diffraction application parallel beam geometry XRD using polycapillary collimating optics can be used to enhance stress and strain analysis of materials. Due to the insensitivity of parallel beam XRD to sample geometry and displacement errors, minimal sample preparation is required for stress/strain analysis of samples. For the same reasons, the technique can be used to monitor on-line changes in a material. Furthermore, through use of a polycapillary collimating optics, the parallel beam XRD system can be combined with a low power X-ray source, reducing instrument size and power requirements for in-line stress or strain measurements.

Parallel Beam X-ray Diffraction geometry using polycapillary collimating optics. This technique has been successfully used for material component analysis, specifically on stressed and unstressed samples of aluminum.