- Analyzers

- Optics & Sources

- Technologies

- Support

- About

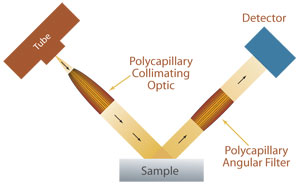

Parallel Beam Geometry for Powder XRD Technique

Some of the major drawbacks of traditional parafocusing XRD for diffraction measurement of powder samples are that it requires very precise source-sample-detector alignment and carefully prepared samples. Errors often result from differences in sample position, shape, roughness, flatness, and transparency. Furthermore, small diffraction intensities may result due to the small parafocusing source irradiation area as the number of crystals in a powder satisfying the Bragg condition depends on the volume irradiated by the beam and the crystallite size.

Parallel beam XRD Technique using polycapillary collimating optics can be used to enhance powder XRD experiments. Due to the insensitivity of parallel beam XRD to sample geometry and displacement errors, minimal sample preparation is required for powder samples. An additional benefit of using a collimated beam for X-ray powder diffraction is to spread the incident beam over a large region, allowing many more crystals to be in diffracting condition compared to the area typically irradiated with a parafocusing instrument.